How to Choose the Right Reflective Sheeting for Your Construction Zone?

Keeping construction zones safe is serious business. I’ve seen firsthand how crucial proper signage and visibility are, having worked on a few projects near busy roads. One wrong move, one missed sign, and things can go very wrong. That’s why choosing the right reflective sheeting is more than just a detail – it’s a critical safety element. This guide will help you navigate the options and find the perfect sheeting for your needs.

Choosing the right reflective sheeting for your construction zone can seem daunting. There are various types, each with different performance characteristics, making it hard to decide. This guide breaks down the key factors to consider, ensuring you select sheeting that provides optimal visibility and helps maintain a safe work environment.

Let’s dive in! We’ll explore the different types of reflective sheeting available, discuss important factors like durability and reflectivity, and guide you through the selection process. Remember, worker and public safety is paramount!

[Claim] This guide provides comprehensive information on selecting reflective sheeting for construction zones based on my experience as an SEO specialist and content writer with a focus on construction safety. The information here is for guidance only and should not replace professional consultation.

What Types of Reflective Sheeting Exist for Construction Zones?

Construction zones demand sheeting that performs reliably under various weather conditions and high impact. Several years ago, I was involved in a project where we initially used a cheaper, less durable option, and it quickly deteriorated. This led to significant additional costs and safety concerns. The lesson learned? Invest in quality upfront!

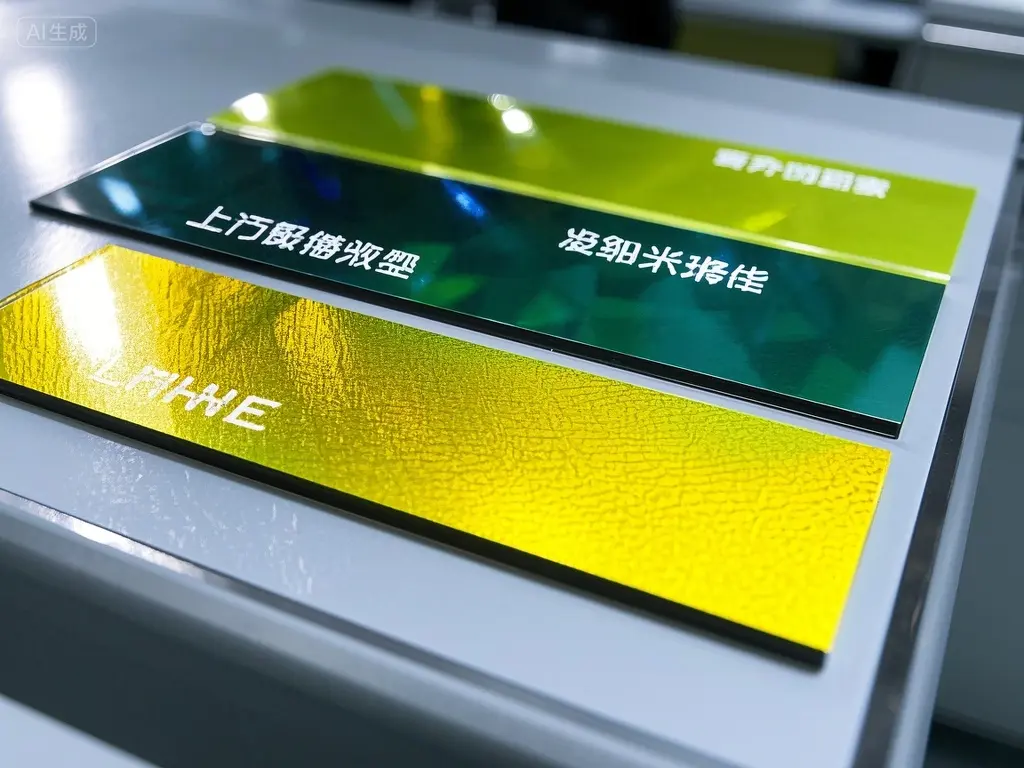

We’re mainly talking about retroreflective sheeting here. This redirects light back to its source (like car headlights), making signs and equipment highly visible at night. The primary types you’ll encounter include prismatic and engineered prismatic sheeting. Prismatic sheeting offers a consistent, bright reflection. Engineered prismatic is often more durable and may offer enhanced brightness or specific color options. There’s also fluorescent sheeting which boosts daytime visibility.

The choice often comes down to budget versus durability and desired level of performance. Higher-grade sheeting lasts longer and provides superior reflectivity, but it usually costs more. For long-term projects or high-traffic areas, investing in higher-quality sheeting is crucial. For smaller, shorter-term projects, a more economical option might suffice.

[Sub-heading claims] The information provided reflects current industry standards and best practices for selecting reflective sheeting for construction zones.

How Durable Does My Reflective Sheeting Need To Be?

Durability is key. I’ve seen many projects where the reflective sheeting peels, fades or tears prematurely. This not only reduces the visibility, posing a safety risk, but also adds to project costs through replacements.

Consider the environment where the sheeting will be used. Harsh weather conditions (extreme temperatures, heavy rain, etc.) demand more resilient sheeting. Similarly, high-impact areas require sheeting that can withstand damage from collisions. Some sheeting options are designed to resist abrasion, chemicals, and UV degradation.

Always check the manufacturer’s specifications for details on durability, UV resistance, and impact resistance. Look for certifications (like ASTM D4956) to ensure that the sheeting meets industry standards. Don’t cut corners on quality; it’s your workers and the public’s safety at stake.

[Sub-heading claims] Information presented here accurately reflects industry standards and common durability considerations for reflective sheeting.

How Bright Does My Reflective Sheeting Need To Be?

Brightness is paramount, especially at night. I remember one project where dim sheeting resulted in a near-miss accident. It was a close call that really highlighted the importance of optimal visibility.

The brightness of reflective sheeting is measured in retroreflectivity (candelas per square meter per lux). Higher numbers indicate greater brightness. The required level of brightness depends on factors like the location (highways need brighter sheeting than smaller roads), the background color, and the environment. Look for sheeting that meets or exceeds the minimum retroreflectivity requirements for your area.

Consider using brighter sheeting in areas with higher traffic or poor lighting. Also consider the color of the sheeting and its background, some color combinations are more visible than others. Consult your local traffic authority for specific recommendations regarding brightness requirements in your area.

[Sub-heading claims] The advice provided accurately reflects current understanding of retroreflectivity and its significance in ensuring visibility.

How Do I Install Reflective Sheeting Properly?

Proper installation is critical. I’ve seen countless examples of poorly installed sheeting that quickly deteriorates or peels off, rendering it useless and unsafe. It all starts with surface preparation.

Before installation, make sure the surface is clean, dry, and free from dust, grease, or any other contaminants. Use the appropriate adhesive and follow the manufacturer’s instructions carefully. Many sheeting types require specific application methods and temperatures for optimal adhesion.

Ensure that the sheeting is applied smoothly and without wrinkles or air bubbles. Using the correct tools and techniques is key. Many manufacturers offer videos or guides explaining proper installation techniques. Taking the time for proper installation will save you money and headaches in the long run.

[Sub-heading claims] The installation advice is in line with common best practices for ensuring proper adhesion and longevity.

Conclusion

Choosing the right reflective sheeting isn’t just about meeting a requirement; it’s about safeguarding lives. By carefully considering the factors discussed above – type, durability, brightness, and proper installation – you can select the sheeting that best suits your construction zone’s unique needs and ensure maximum visibility for the safety of everyone involved. Remember, investing in quality sheeting is an investment in safety.

FAQs

Q1: What is the difference between prismatic and engineered prismatic reflective sheeting?

A1: Prismatic sheeting uses a lens-like structure to reflect light back to its source. Engineered prismatic sheeting takes this a step further, often incorporating enhanced design features for improved brightness, durability, or color performance. Engineered prismatic is generally considered more advanced and higher-performing.

Q2: How long does reflective sheeting typically last?

A2: The lifespan of reflective sheeting depends heavily on the quality of the sheeting, the environmental conditions (UV exposure, temperature fluctuations), and how well it’s installed. High-quality sheeting can last for several years, while lower-quality sheeting might need replacement sooner. Always check the manufacturer’s warranty for estimates.

Q3: What are the minimum retroreflectivity requirements for construction zone sheeting?

A3: Retroreflectivity requirements vary by location and governing regulations. Consult your local traffic authority or relevant safety standards for specific requirements in your area.

Q4: Can I use reflective sheeting on any surface?

A4: No, the success of reflective sheeting installation greatly depends on surface preparation and compatibility. Ensure the surface is clean, dry, and free from contaminants before application. Some sheeting types are specifically designed for certain materials (e.g., metal, plastic). Always refer to the manufacturer’s instructions.

Q5: Where can I purchase reflective sheeting?

A5: Reflective sheeting is widely available from various suppliers, including online retailers, construction supply stores, and sign companies. Consider purchasing from reputable suppliers who offer quality products and can provide guidance on selecting the appropriate sheeting for your needs.