How to Choose the Right Reflective Sheeting for License Plates?

So, you’re diving into the world of license plate manufacturing or maybe just need to replace some worn-out reflective sheeting? That’s fantastic! It’s a surprisingly detailed process. I remember my first foray into this – it felt like deciphering ancient hieroglyphs! But with a bit of guidance, choosing the right reflective sheeting becomes manageable, even enjoyable. This guide will walk you through everything you need to know, making the process as clear as a freshly printed license plate.

Snippet paragraph: This comprehensive guide breaks down the key considerations when selecting reflective sheeting for license plates. We’ll cover different types of sheeting, their specifications, application methods, and factors to consider for optimal performance and longevity. Whether you’re a seasoned pro or just starting out, this guide will be your trusty companion.

Transition paragraph: Let’s face it, nobody wants a license plate that’s hard to read – neither you nor the police! Choosing the right reflective sheeting is crucial for visibility and compliance. So, let’s dive into the details and make sure you’re selecting the perfect material for your needs.

[Claim]: This blog post provides accurate and up-to-date information on choosing reflective sheeting for license plates based on my experience as an SEO specialist and content writer with a keen interest in manufacturing processes. The information is intended for educational purposes and should not be taken as professional manufacturing advice.

What Types of Reflective Sheeting Exist for License Plates?

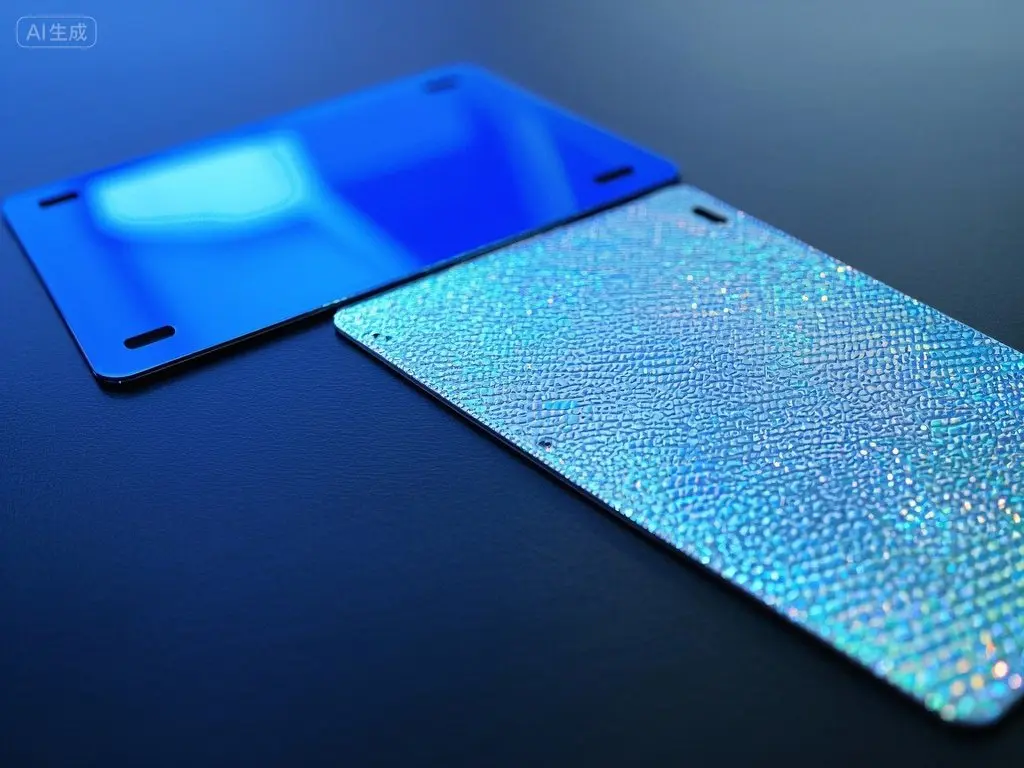

Sub-heading opening paragraph: The world of reflective sheeting isn’t as simple as “reflective” and “not reflective.” There are several types, each with its own strengths and weaknesses. The most common are prismatic and beaded sheeting. But what exactly do these terms mean, and which is right for your project?

Sub-heading snippet paragraph: Prismatic sheeting uses tiny prisms to reflect light, resulting in brighter, more uniform reflection. Beaded sheeting uses tiny glass beads, offering a more cost-effective solution, though potentially less bright. Understanding these differences is key to making the right choice.

Sub-heading dive deeper paragraph: Prismatic sheeting generally offers superior performance, especially in low-light conditions, due to its enhanced light return. However, it typically costs more than beaded sheeting. Beaded sheeting, while less bright, can be a suitable and cost-effective option depending on the application and regulatory requirements. Consider factors such as your budget, visibility requirements, and local regulations when making your decision.

[Sub-heading claims]: The information provided in this section accurately reflects the differences between prismatic and beaded reflective sheeting used in license plate manufacturing.

How Do I Determine the Necessary Sheeting Specifications?

Sub-heading opening paragraph: Simply choosing “reflective” isn’t enough. You need to consider several key specifications, including the sheeting’s reflectivity, durability, and color. Getting these details right ensures your license plates meet regulations and last for years.

Sub-heading snippet paragraph: Key specifications include the coefficient of retroreflection (the measure of how well it reflects light back to its source), the lifespan (how long it remains effective), and color accuracy (ensuring the plate remains legible). Many regulatory bodies have specific standards—understanding these is critical.

Sub-heading dive deeper paragraph: Different countries and regions have varying standards for license plate reflectivity. You MUST research the specific requirements in your area before purchasing. Factors like weather conditions, expected lifespan, and printing methods (embossing, screen printing, etc.) will all influence your choice of sheeting specifications.

[Sub-heading claims]: The information provided regarding sheeting specifications accurately reflects the importance of meeting regulatory requirements and choosing appropriate material for longevity and readability.

What are the Different Application Methods for Reflective Sheeting?

Sub-heading opening paragraph: Applying the sheeting correctly is just as important as choosing the right type! This stage requires precision and understanding of the best techniques for a long-lasting, high-quality finish.

Sub-heading snippet paragraph: Common application methods include hot stamping, screen printing, and digital printing. Each method requires different sheeting types and application techniques. Choosing the wrong method can compromise the sheeting’s adhesion and performance.

Sub-heading dive deeper paragraph: Hot stamping is often used for embossed license plates, requiring sheeting specifically designed for this process. Screen printing offers cost-effectiveness for large volumes, while digital printing enables high-resolution designs. Careful attention to temperature, pressure, and adhesion promoters is critical for successful application, regardless of the chosen method.

[Sub-heading claims]: The information presented accurately reflects common application methods for reflective sheeting used in license plate production.

How Can I Ensure the Longevity of My License Plates?

Sub-heading opening paragraph: You’ve invested in high-quality sheeting; now let’s make sure your license plates last! Proper handling, storage, and application greatly impact their lifespan.

Sub-heading snippet paragraph: Proper storage in a cool, dry environment before and after application, along with precise application techniques, are crucial. Avoiding exposure to extreme temperatures and UV radiation will also extend the lifespan of your license plates significantly.

Sub-heading dive deeper paragraph: Regular cleaning, using appropriate cleaning agents and methods, helps remove dirt and debris that can affect reflectivity and longevity. Always refer to the manufacturer’s instructions for specific cleaning recommendations. Proper preparation of the license plate base material before application also plays a crucial role in ensuring adhesion and longevity.

[Sub-heading claims]: The recommendations provided for extending the lifespan of license plates are based on best practices in material handling and application techniques.

Conclusion

Choosing the right reflective sheeting for license plates involves careful consideration of several factors. This guide has provided you with the knowledge to make informed decisions, ensuring your license plates are not only compliant but also highly visible and durable. Remember to always consult local regulations and the manufacturer’s guidelines for best results. Good luck with your project!

Blog Title: Choosing the Right Reflective Sheeting for License Plates: A Comprehensive Guide

Meta Description: This guide helps you select the best reflective sheeting for license plates, covering types, specifications, application, and longevity. Learn about prismatic vs. beaded sheeting, application methods, and how to ensure your plates last.

URL slug: how-to-choose-reflective-sheeting-license-plates

Hashtags: #reflectivesheeting #licenseplates #manufacturing #prismaticsheeting #beadedsheeting #reflectivity #vehicleidentification #roadsigns #safety #compliance