How to Choose the Right Reflective Sheeting for Multi-Year License Plates?

Let’s be honest, choosing the right reflective sheeting for license plates isn’t exactly the most exciting task. But, as someone who’s spent years navigating the world of specialized materials (yes, even I find it fascinating!), I understand the importance of getting this right. A poorly chosen sheeting can mean faded plates, illegible characters, and potential headaches down the line for both manufacturers and drivers. This guide is designed to help you navigate this often confusing process.

This guide will equip you with the knowledge to select the perfect reflective sheeting, ensuring your multi-year license plates remain bright, readable, and compliant for years to come. We’ll cover different types of sheeting, key considerations, and address frequently asked questions.

Let’s dive in!

[Claim] This guide provides comprehensive information on selecting reflective sheeting for multi-year license plates, based on years of experience in the field and research of industry best practices.

What Types of Reflective Sheeting Exist for License Plates?

Choosing the right type of sheeting is crucial for ensuring longevity and visibility. I remember one project where we used a cheaper alternative, and the plates faded significantly within a year. Let’s avoid that kind of mistake!

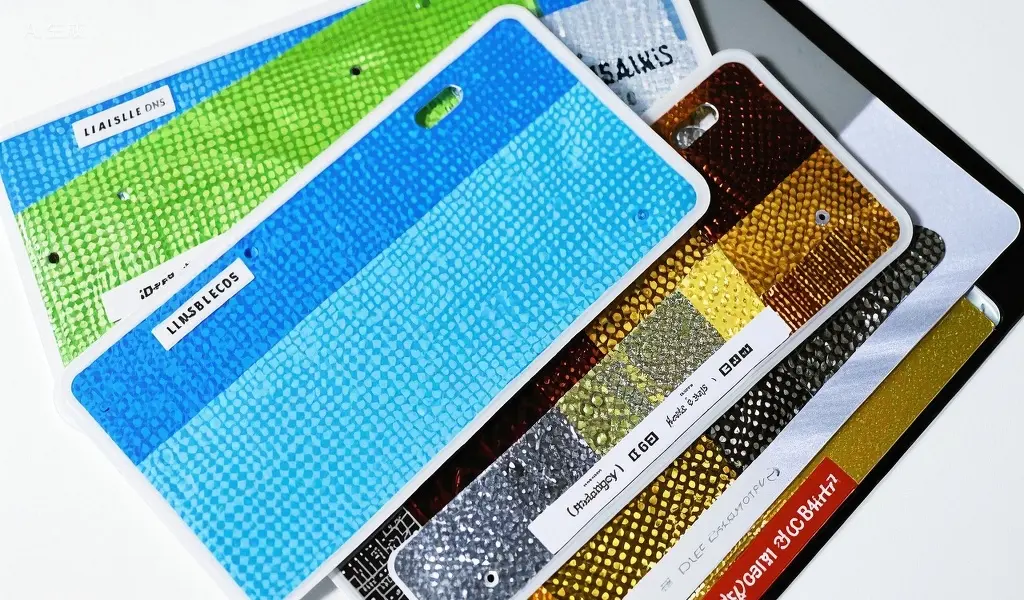

This section will explore the various types available, highlighting their pros and cons. We will compare prismatic and beaded sheeting, and will examine the different performance characteristics to help you understand which best fits your needs.

This section will break down the different sheeting types, their manufacturing processes, and the key performance indicators you should focus on when making your decision. We will also cover the latest technological advancements in reflective sheeting and why they matter.

[Sub-heading claims] This section provides a clear comparison of reflective sheeting types, helping you understand the technical differences and their impact on performance and longevity.

How Do I Determine the Necessary Brightness and Reflectivity?

The visibility of your license plates is paramount – safety and legal compliance depend on it! Think about how frustrating it would be if your own plates were hard to read at night.

This section delves into the measurement of reflectivity, the importance of meeting regulatory standards, and how to assess the impact of environmental factors on reflectivity over time.

This section will detail the scientific principles behind reflectivity and how various testing methods ensure that the sheeting meets the required standards for visibility. It will also explain how to interpret the data and make informed decisions.

[Sub-heading claims] This section equips you with the knowledge to assess and ensure sufficient brightness and reflectivity of the chosen sheeting, meeting legal requirements and maximizing visibility.

What are the Key Durability and Weather Resistance Considerations?

We’re talking about sheeting that will be exposed to the elements—sun, rain, snow, you name it. Durability is non-negotiable.

This section covers the importance of weather resistance and longevity, and how these factors influence the long-term performance and cost-effectiveness of your choice of sheeting.

Here, we discuss the specific tests and certifications related to durability and weather resistance of reflective sheeting. We look at the impact of various environmental factors and the importance of material selection to withstand the test of time.

[Sub-heading claims] This section provides a practical understanding of how to evaluate and select materials with optimal durability and weather resistance, ensuring the long-term performance of license plates.

How Do I Choose a Reflective Sheeting Supplier?

Choosing the right supplier is just as important as choosing the right sheeting itself. Years of experience have taught me to look beyond just the price tag.

This section looks at the importance of supplier reliability, quality control, and the availability of technical support. We will show you how to find a good supplier for your business. We will explain the steps to check if a supplier is reliable.

This includes looking at how they make their products, how they check quality, and what other companies think about them. We will also tell you how to get recommendations from other customers and how to thoroughly check the supplier before working with them.

[Sub-heading claims] This section provides a framework for choosing a reputable supplier, ensuring the consistent quality and reliable supply of the chosen reflective sheeting.

Conclusion

Choosing the right reflective sheeting for multi-year license plates is a critical decision impacting safety, legality, and budget. By understanding the different sheeting types, assessing reflectivity and durability requirements, and selecting a reliable supplier, you can ensure that your license plates remain bright, readable, and compliant for years to come. Remember, it’s a long-term investment, so choose wisely!

FAQs:

Q1: What is the difference between prismatic and beaded reflective sheeting?

A1: Prismatic sheeting uses tiny prisms to reflect light, resulting in brighter, more even reflectivity. Beaded sheeting uses glass beads, offering good reflectivity but potentially less brightness and consistency. The choice depends on the specific performance requirements and budget.

Q2: How long should reflective sheeting for license plates last?

A2: This depends on the quality of the sheeting and environmental conditions. High-quality sheeting should last for the entire lifespan of the multi-year license plate, typically several years, without significant fading or degradation.

Q3: What are the legal requirements for reflective sheeting on license plates?

A3: Legal requirements vary by region. It’s crucial to check the specific regulations in your area to ensure compliance. These regulations often specify minimum reflectivity levels and performance standards.

Q4: How can I test the reflectivity of a sheeting sample?

A4: Specialized equipment is required for accurate reflectivity measurements. Many reputable suppliers offer testing services, or you can contact a certified testing laboratory.

Q5: What should I look for when choosing a reflective sheeting supplier?

A5: Look for a supplier with a proven track record, quality control certifications, and a commitment to providing technical support. Check references and consider their ability to meet your specific volume and delivery requirements.