License Plate Manufacturing Process Comparison: Aluminum vs Acrylic

I. Aluminum + Reflective Film License Plate Manufacturing Process

Raw Materials Preparation

1. Aluminum Plate

Used as the base material for license plates, typically 0.5-1.2mm thick aluminum sheets

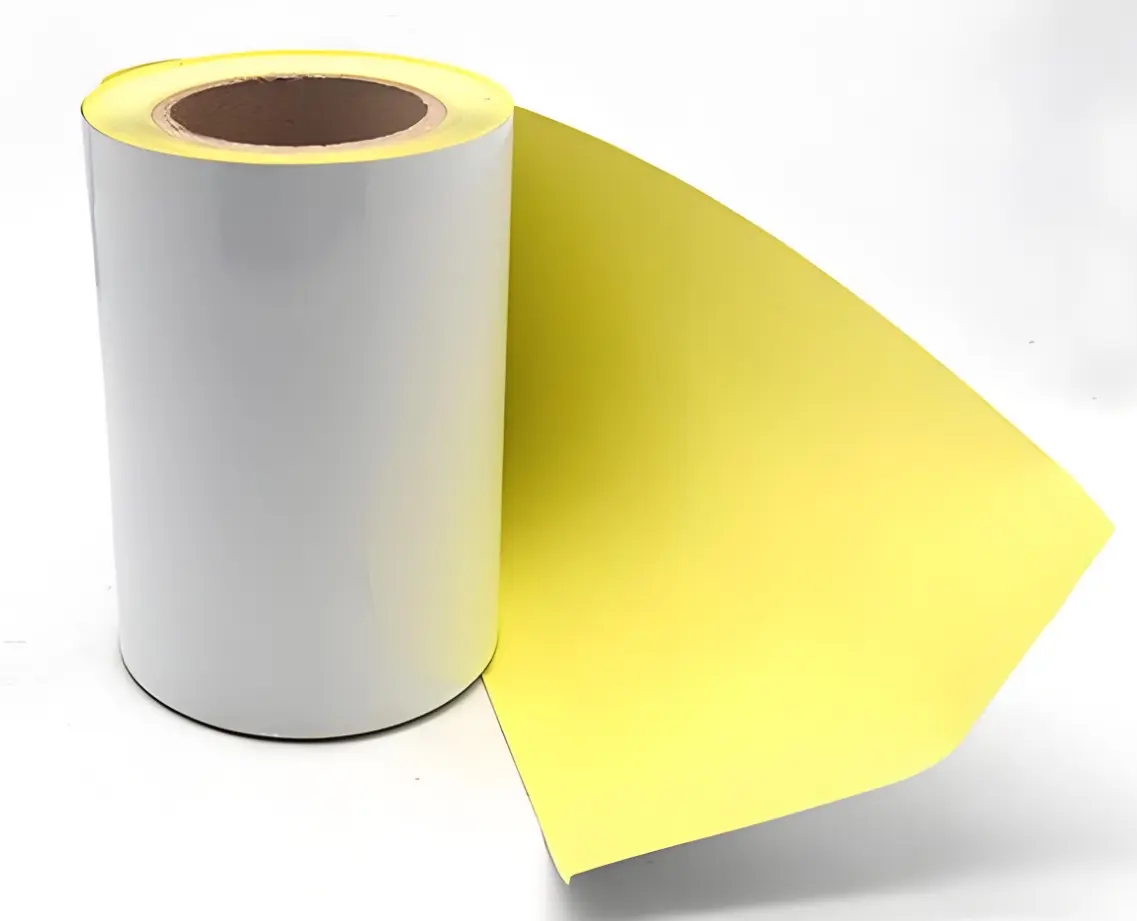

2. Reflective Film

Specialized reflective film for license plates, main types include:

- Embossable reflective film (e.g., JX800, JX6300)

- Non-embossable reflective film (e.g., JX610)

3. Hot Stamping Foil

Material used to color the embossed characters

Manufacturing Steps

1. Aluminum Preparation and Straightening

- Unroll the aluminum coil using a coil unwinding machine

- Straighten the aluminum sheet using a flattening machine

- Ensure the plate surface is clean and free of contaminants

2. Reflective Film Lamination

- Apply the reflective film to the aluminum surface

- The reflective film contains primary colors, decorative elements, and reflective coating

- The lamination process must avoid bubbles, typically done using automated equipment

3. Cutting

- Cut the laminated aluminum sheets into standard-sized license plate blanks

- Use precision cutting equipment to ensure accurate dimensions

4. Character Embossing

- Place the license plate number die into the embossing machine

- Position the license plate blank

- Set temperature and time parameters

- Activate the embossing machine to use hydraulic pressure to raise characters

- Ensure all characters are aligned evenly

5. Character Coloring

- Use hot stamping foil (black, red, or blue)

- Transfer color to the raised characters using a heat press

- This step creates a strong contrast between characters and background, improving readability

6. Quality Inspection

- Check the quality of character embossing

- Ensure reflective effect meets standards

- Detect any defects or imperfections

7. Edge Processing and Finishing

- Process the license plate edges to ensure no sharp edges

- Punch mounting holes for installation (Optional)

II. Acrylic + Reflective Film License Plate Manufacturing Process

Raw Materials Preparation

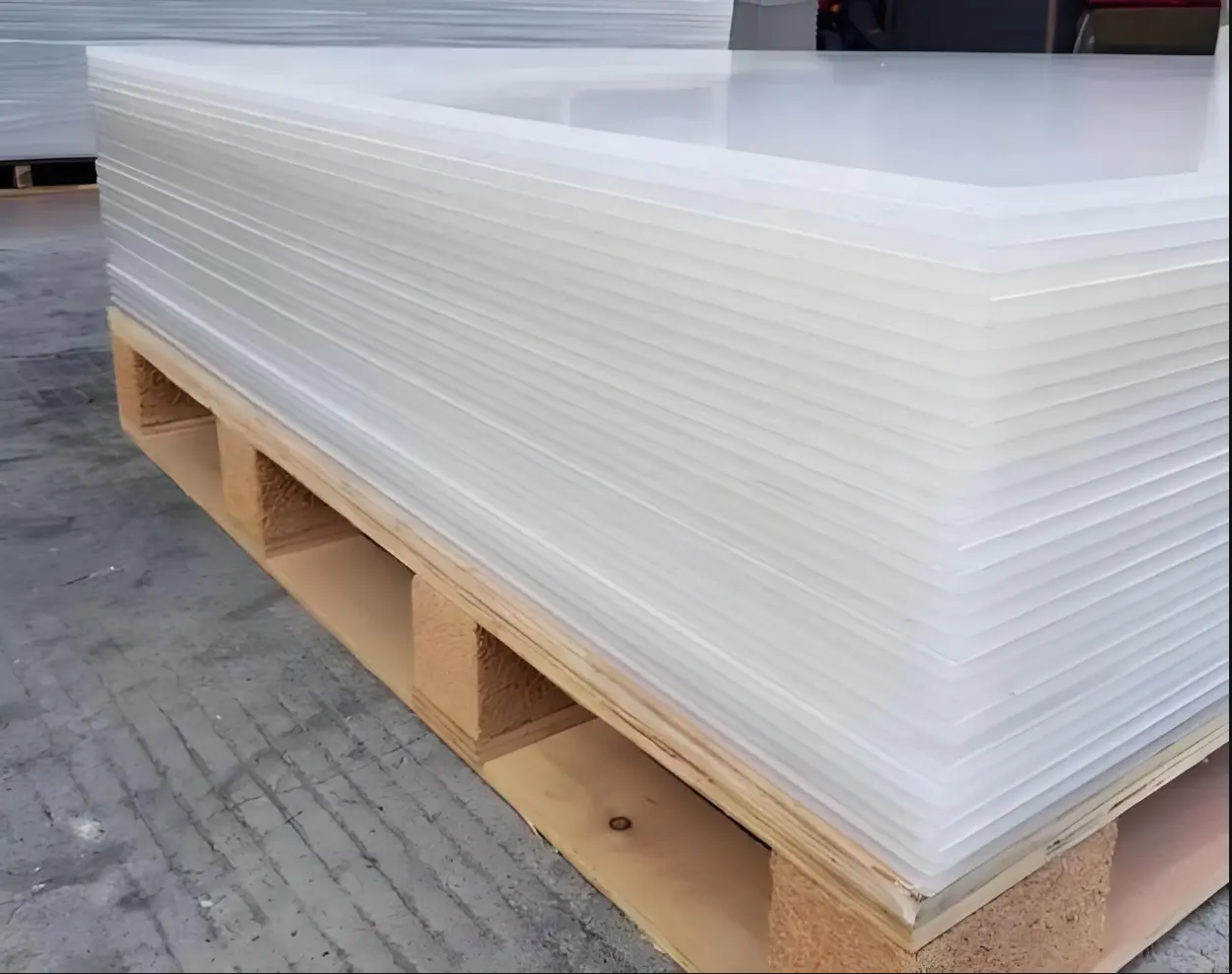

1. Acrylic Panel

Typically 3-5mm thick transparent or colored acrylic panels

2. Reflective Film

Specialized reflective film for acrylic license plates, main types include:

- Non-adhesive reflective film (e.g., XW7201)

- Surface adhesive reflective film (e.g., XW5600/XW5700)

3. Printing Equipment

Laser printer or thermal printer

Manufacturing Steps

1. Acrylic Panel Preparation

- Select appropriate size and thickness of acrylic panel

- Color and logo could be preprinted on the acrylic panel

- Ensure the surface is clean and scratch-free

- Remove the protective film from the acrylic panel surface

2. Reflective Film Preparation

- Embossable reflective film (e.g., JX800, JX6300)

- Non-embossable reflective film (e.g., JX610)

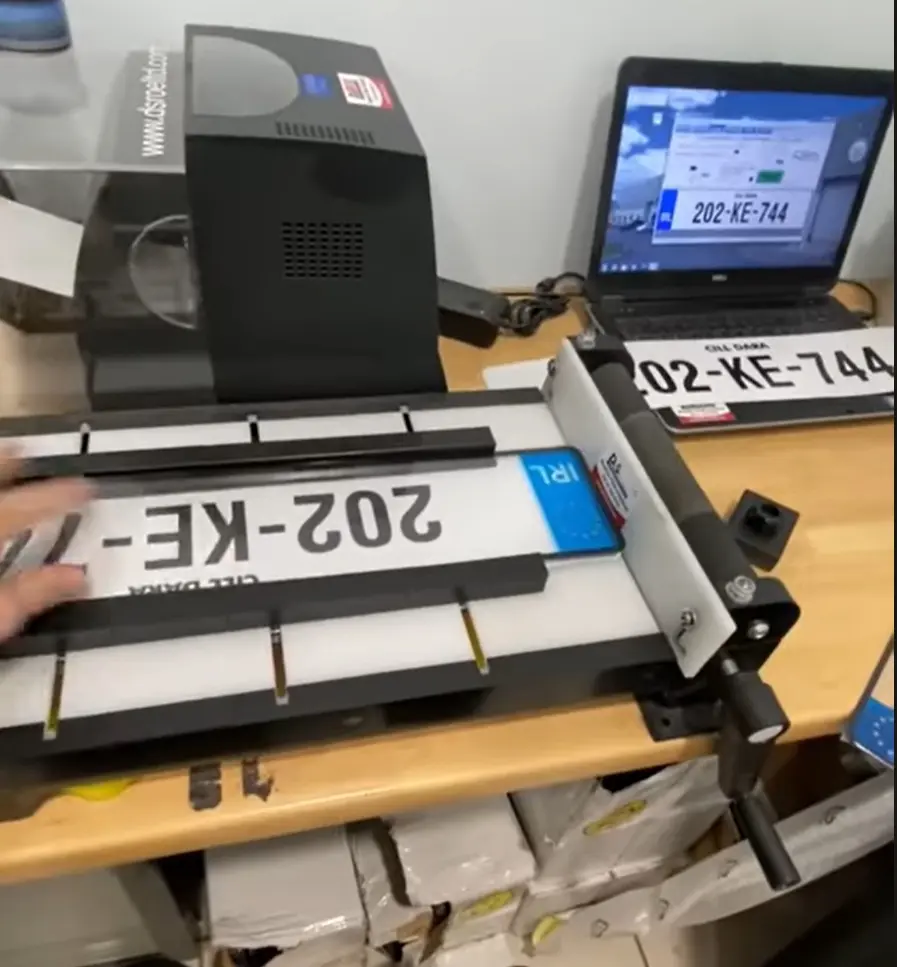

3. Design and Printing

- Use design software to create license plate patterns and characters

- Print characters and patterns on the reflective film

- Combine the printed reflective film with the acrylic panel

4. Lamination

- Laminate the printed reflective film with the acrylic panel

- For surface adhesive reflective film, ensure complete adhesion to the acrylic panel

- For non-adhesive reflective film, place it between the acrylic panel and a transparent protective layer

5. Edge Processing

- Polish and smooth the edges of the cut acrylic panel

- Ensure edges are smooth without burrs

6. Final Assembly

- Add waterproof frame if necessary

- Perform final quality inspection to ensure clear patterns and standard text

III. Comparison of the Two Manufacturing Processes

| Characteristic | Aluminum + Reflective Film | Acrylic + Reflective Film |

|---|---|---|

| Weight | Heavier | Lighter |

| Durability | High, resistant to bending and impact | Medium, easily scratched but doesn’t rust |

| Manufacturing Difficulty | Requires specialized embossing and heat pressing equipment | Mainly relies on laser printing and cutting equipment |

| Cost | Medium (high equipment cost, moderate material cost) | Lower (less equipment investment, moderate material cost) |

| Reflective Effect | Better, raised characters enhance visibility | Good, flat printing |

| Customization Flexibility | Limited by embossing dies | High, designs and content can be modified anytime |

| Application Range | Official license plates, scenarios requiring high durability | Temporary plates, decorative plates, personalized customization |

| Production Efficiency | High efficiency for mass production | Flexible for small batch and customized production |

Aluminum License Plate Finished Product

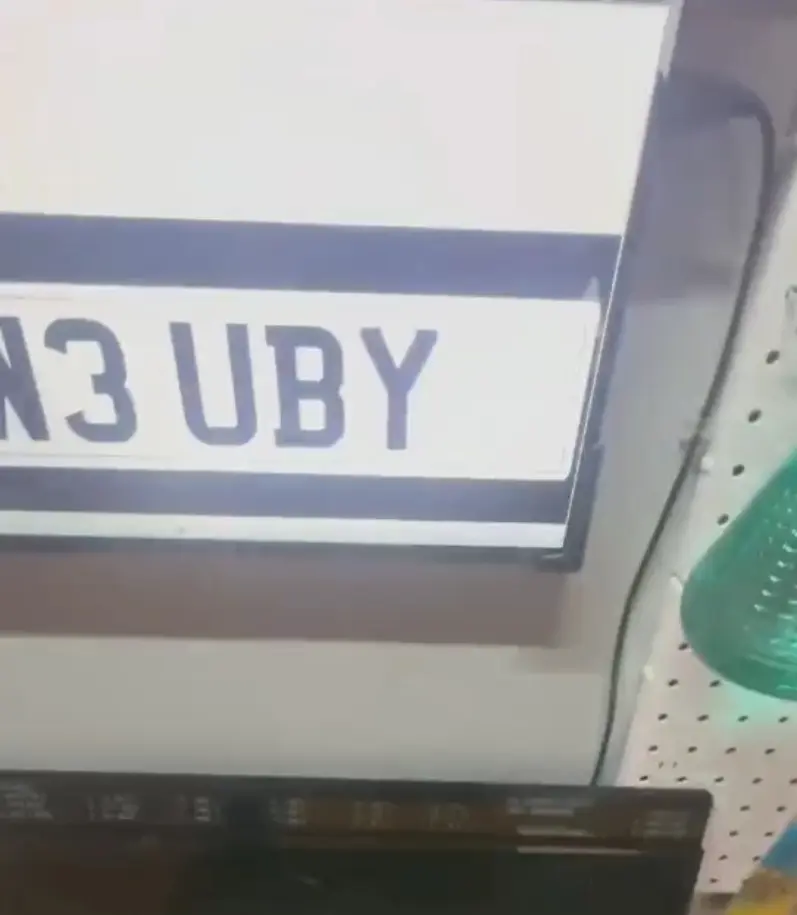

Acrylic License Plate Finished Product

IV. Summary

Aluminum + Reflective Film License Plates are suitable for large-scale standardized production, with excellent durability, making them the primary manufacturing method for official license plates. Their raised characters and reflective properties provide good visibility under various lighting conditions.

Acrylic + Reflective Film License Plates have a relatively simple manufacturing process that doesn’t require specialized embossing equipment, mainly relying on laser or thermal printing technology. They are lightweight, cost-effective, and ideal for personalized customization and small-batch production, though less durable than aluminum plates.

Regardless of the chosen manufacturing process, license plates must comply with local regulations, use qualified reflective materials, and ensure clear, identifiable characters to meet basic traffic safety requirements.