Product Overview

SH104 Prismatic Sheeting is a microprismatic retroreflective sheeting for regulatory and warning signing, temporary work zone signing, delineators, and other traffic safety applications. SH104 has a cellular product construction and meets the performance requirements of ASTM D-4956 Type IV, AASHTO M-268 Class B, Mexico N-CMT-05-03-001/13 Type A, EN-12899 Class RA2, and many other industry specifications.

Key Features

- Bright daytime color to maximize daytime visibility.

- Microprismatic optical elements aligned in multiple directions for a more uniform reflective appearance across different rotations.

Physical Characteristics & Properties

- Durability: Up to 7 – 10 years when properly installed. Vertical exposure only.

- Retroreflective Elements: Microprisms

- Adhesive: Permanent, acrylic pressure sensitive adhesive.

- Recommended Substrates: Flat sign panels made from aluminum, galvanized steel and other flat sign substrates. Not recommended for wood substrates. A second high-tack adhesive option is available for use on certain plastics.

- Film Thickness: 17 mils (425 microns)(excludes the release liner)

- Application Temperature: 18°C (65°F) minimum

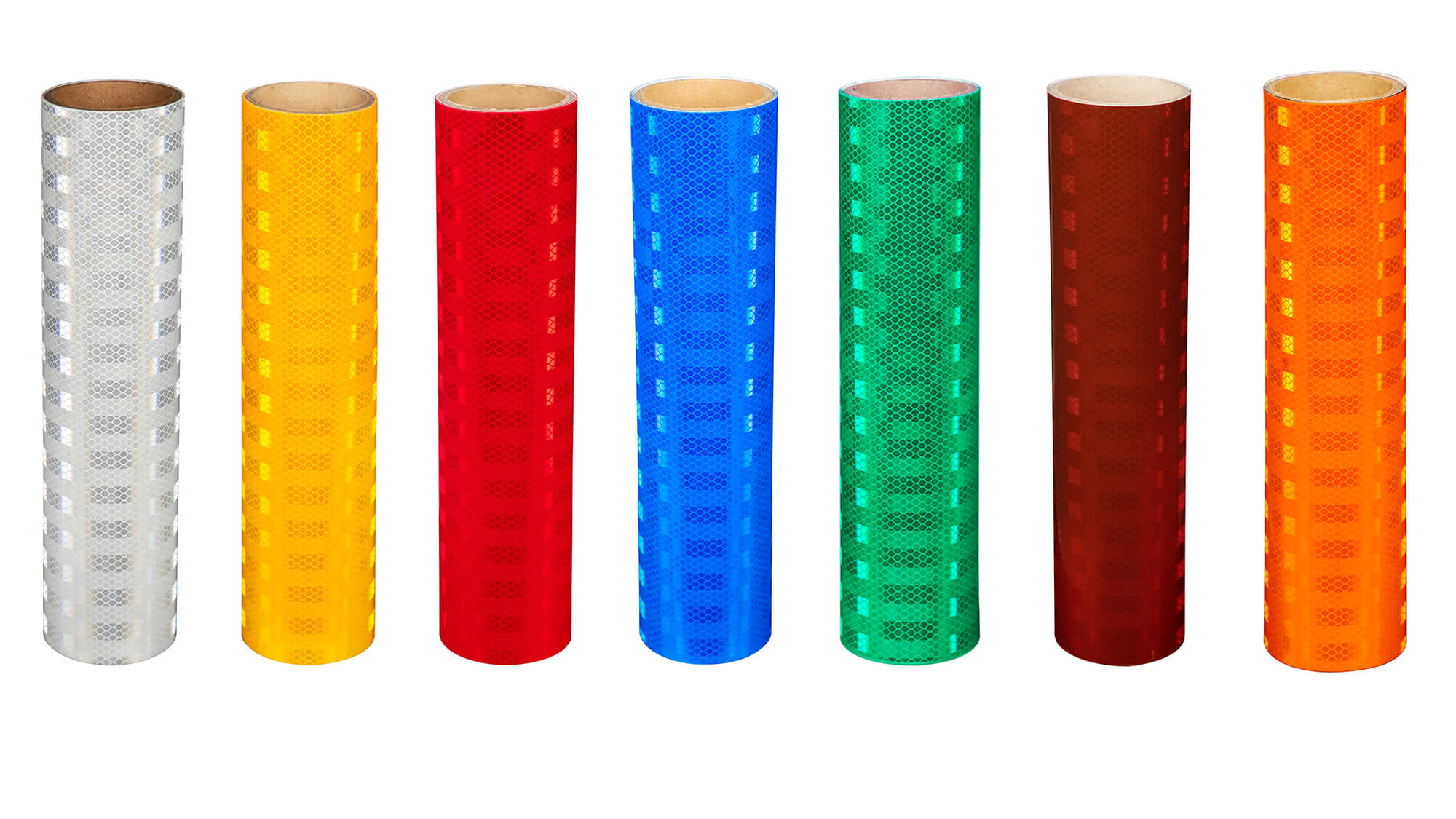

Color Availability

Product Code Color

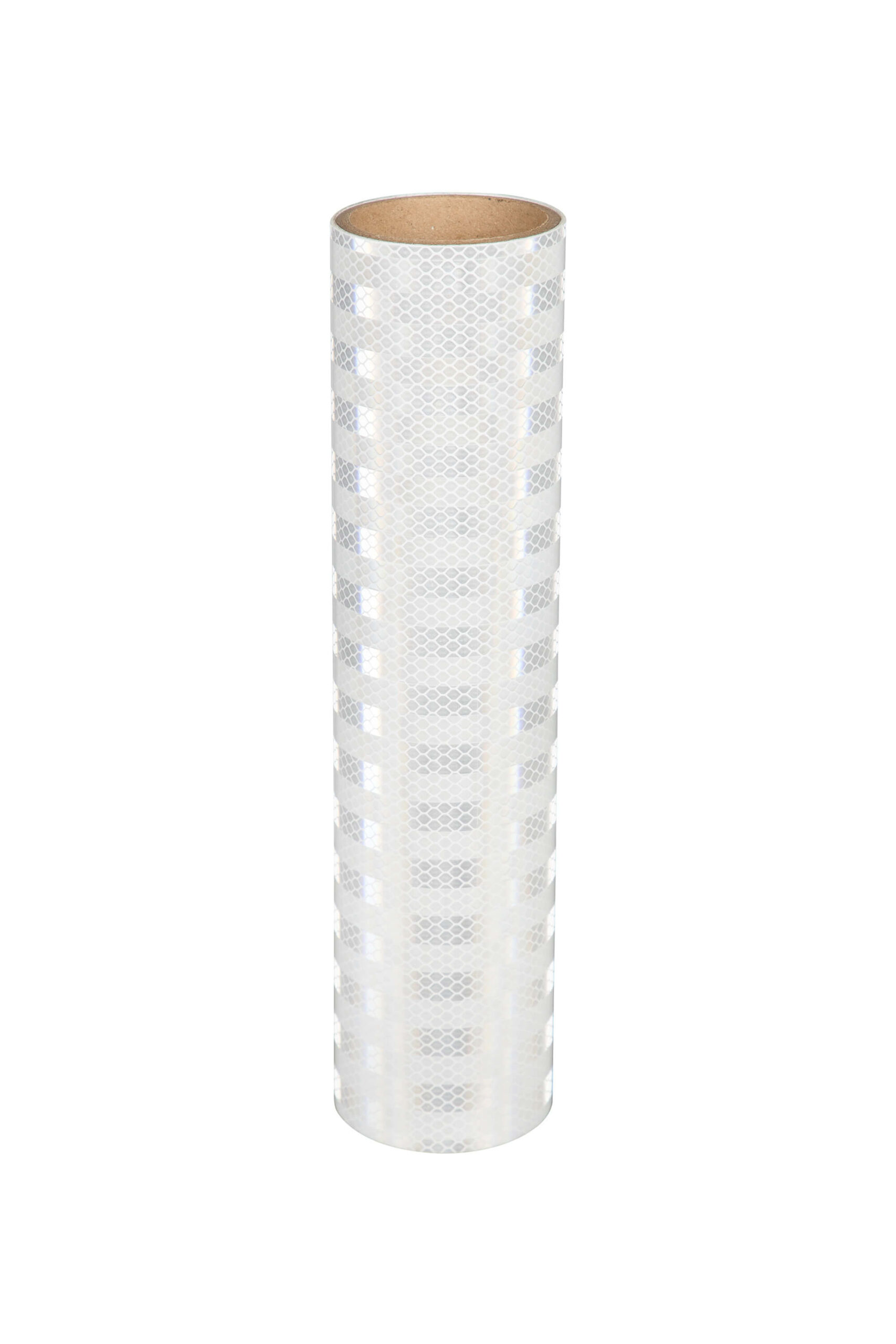

SH-1041 White

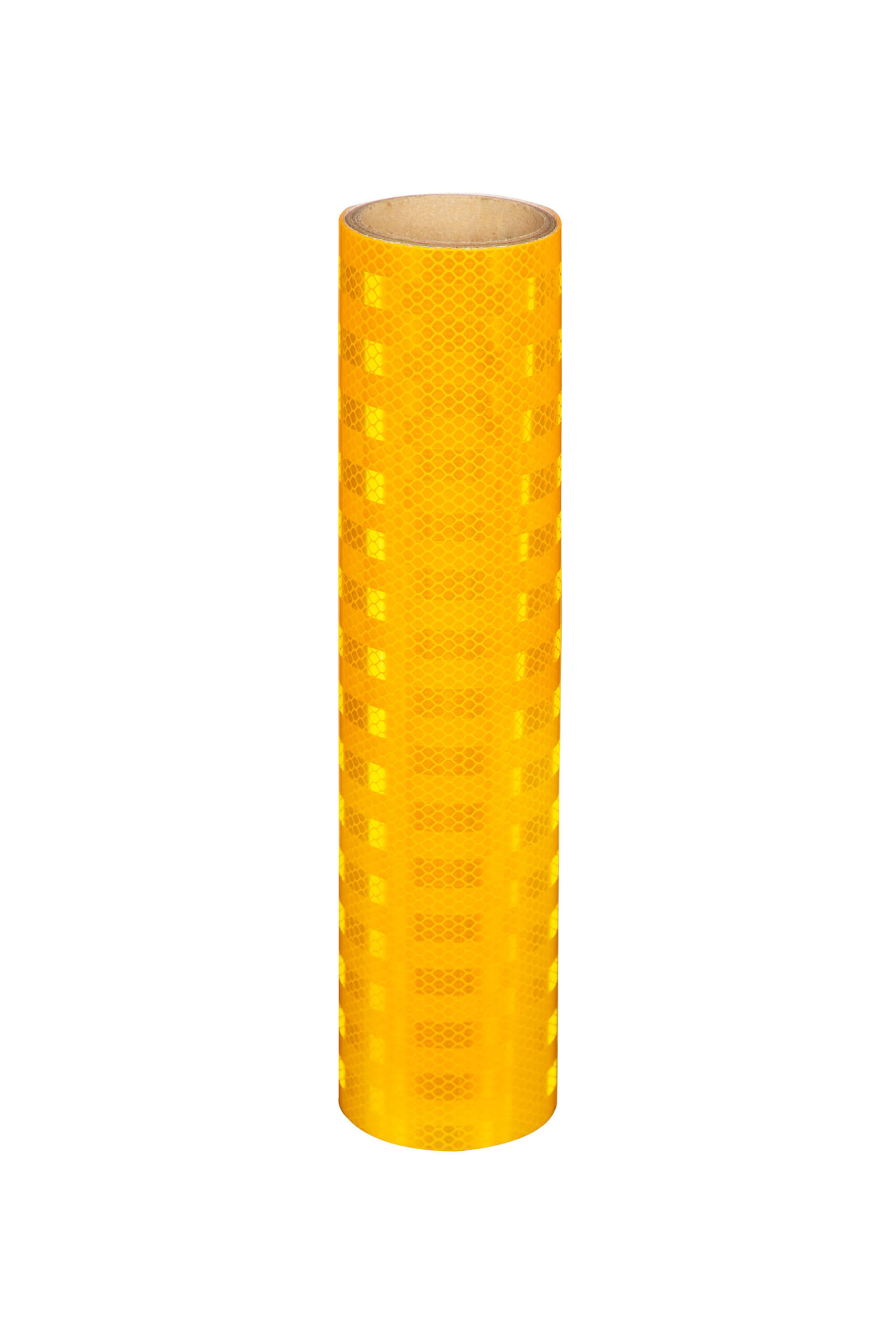

SH-1042 Yellow

SH-1043 Red

SH-1044 Green

SH-1045 Blue

SH-1046 Orange

SH-1047 Brown

SH-1049 Fluorescent Yellow and Green

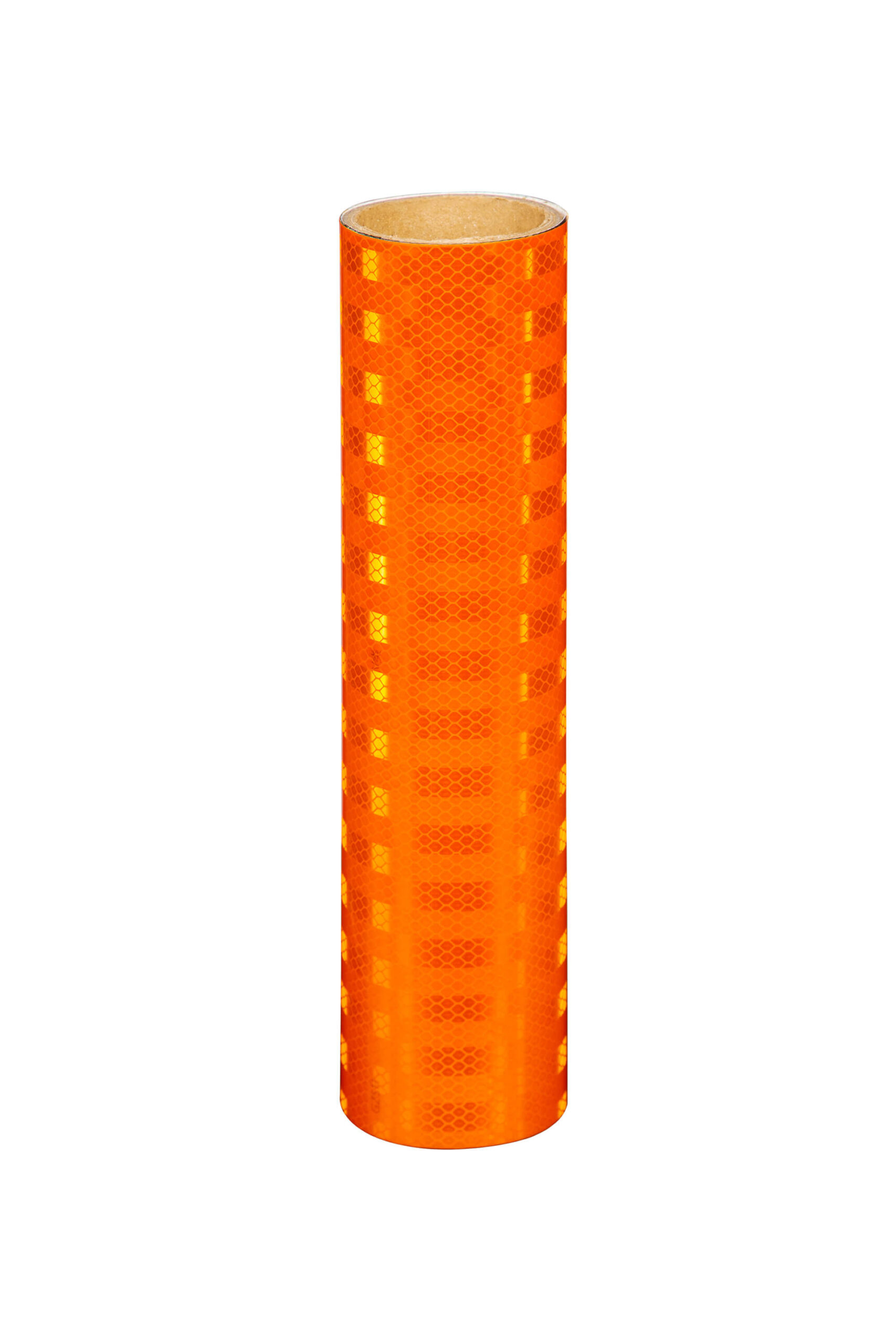

SH-10410 Fluorescent Orange

SH-10411 Black and Yellow

Typical Retroreflection

Typical Coefficient of Retroreflection when Measured per ASTM E-810. Average of 0° and 90° Rotations. (cd/lx/m2)

| Color | Observatoin | Entrance Angle | |

| Angle | -4°/5° | 30° | |

| White | 0.2° | 420 | 240 |

| 0.33° | 225 | 170 | |

| 0.5° | 210 | 110 | |

| 1.0° | 65 | 40 | |

| Yellow | 0.2° | 300 | 170 |

| 0.33° | 160 | 120 | |

| 0.5° | 150 | 75 | |

| 1.0° | 40 | 25 | |

Application Guidelines

The following is a short overview of application guidelines. Please refer to the various Technical Data Bulletins supplied by SH Optical Tech for a complete set of procedures. SH104 should be conditioned above 18°C (65°F) for at least 24-hours prior to application. Application should occur using a squeeze roll applicator with a firm rubber roller. Hand application in not recommended.

SH104 is designed primarily for application to flat surfaces. Sign substrates should be cleaned prior to application. Wipe surfaces with rubbing alcohol (or similar solvent cleaner) and allow the surface to completely dry prior to application. Wet application method is NOT recommended. After lamination, finished signs should be stored indoors at ambient temperatures for at least 24 hours prior to installation or exposure to outdoor environments. Store finished signs on edge in an upright position. Do not stack in outdoor environments or allow sign packages to become saturated with water. Store sign packages indoors in an upright position.

Storage

Store in a cool, dry area. Use within 1-year of receipt of the product.