Product Overview

SH102 Prismatic Sheeting is a microprismatic retroreflective sheeting with up to 5-years durability for commercial signing, construction work zone signing, traffic signing, and similar applications. SH102 has a cellular product construction and contains a proprietary top-coat for exceptional digital printing. Meets the color and reflectivity requirements of ASTM D-4956 Type 1, EN 12899-1 Class 1, and other industry specifications.

Key Features

- Exceptional digital printing across a broad range of printing technologies, including eco-solvent and latex printing.

- Microprismatic optical elements aligned in multiple directions for a more uniform reflective appearance across different rotations.

- Vibrant daytime appearance

Physical Characteristics & Properties

- Durability: Up to 7-years when properly installed. Vertical exposure only. (Note: 3-years for construction work zone colors)

- Retroreflective Elements: Microprisms

- Product Thickness: 16 mils, excluding release liner

- Release Liner: Poly Release Liner

- Adhesive: Permanent acrylic-based pressure sensitive adhesive

- Application Temperature: 15°C (60°F) minimum Suitability of the product for a specific sign substrate should always be tested prior to sign fabrication.

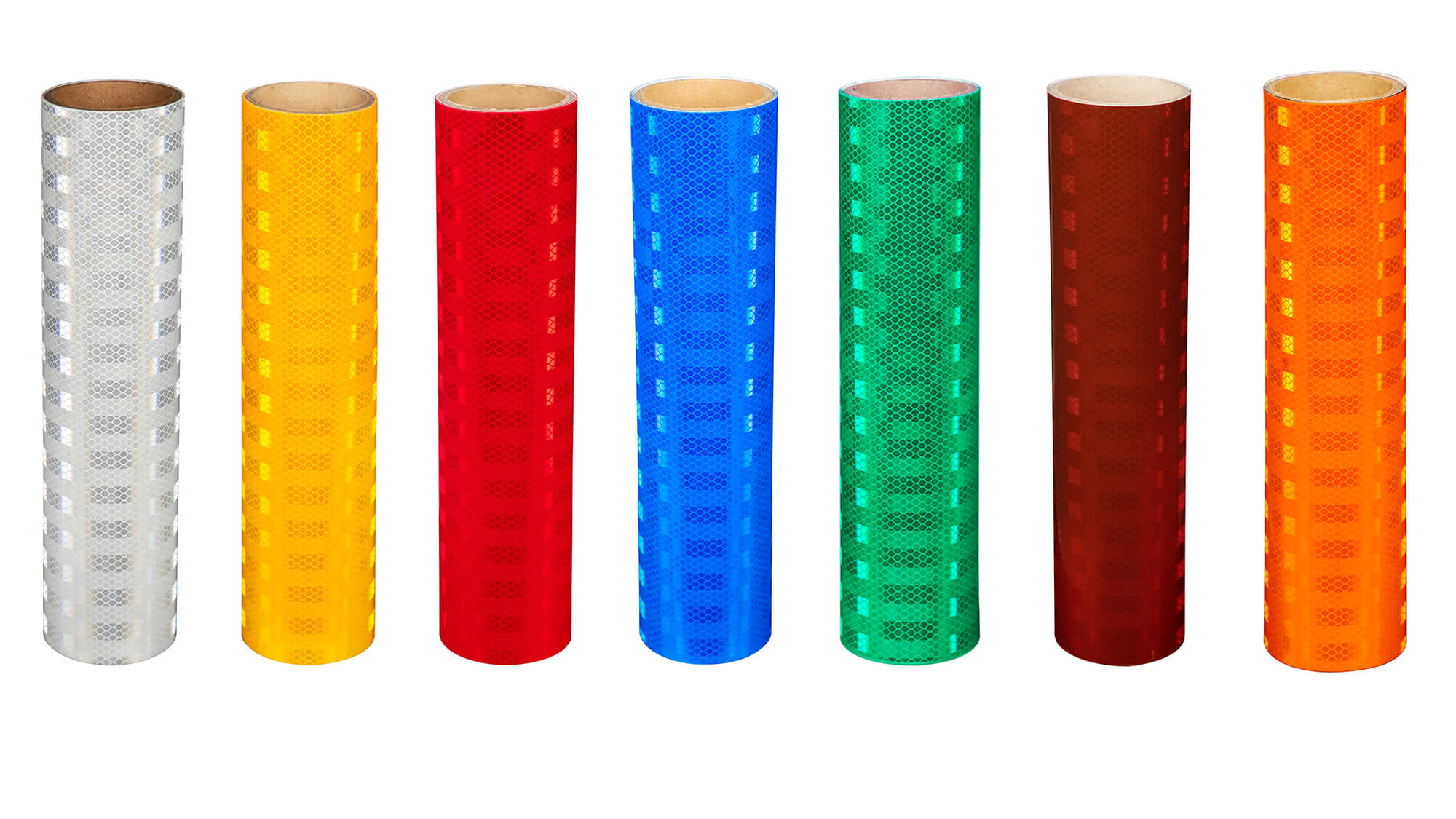

Color Availability

Product Code Color

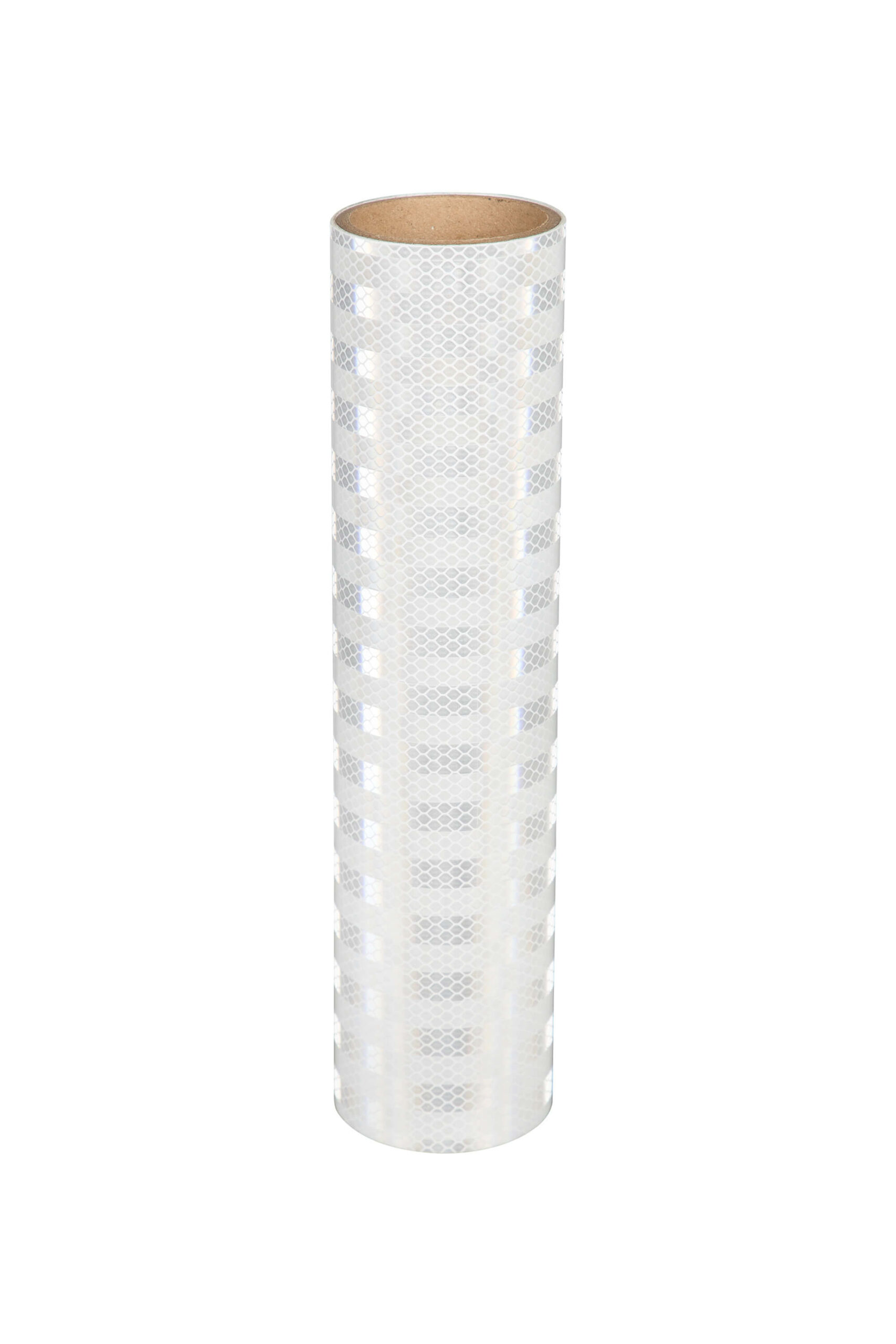

SH-1021 White

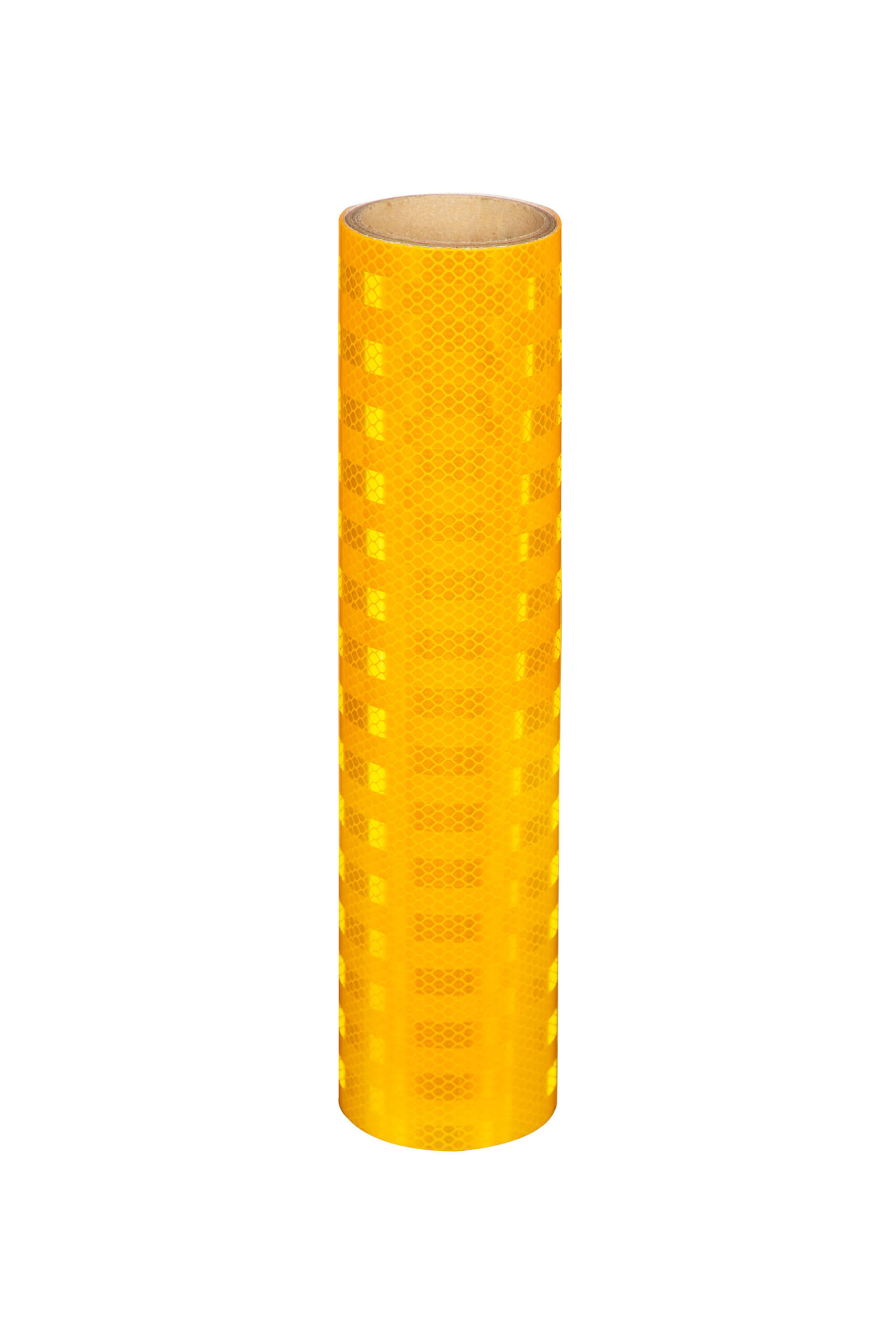

SH-1022 Yellow

SH-1023 Red

SH-1024 Green

SH-1025 Blue

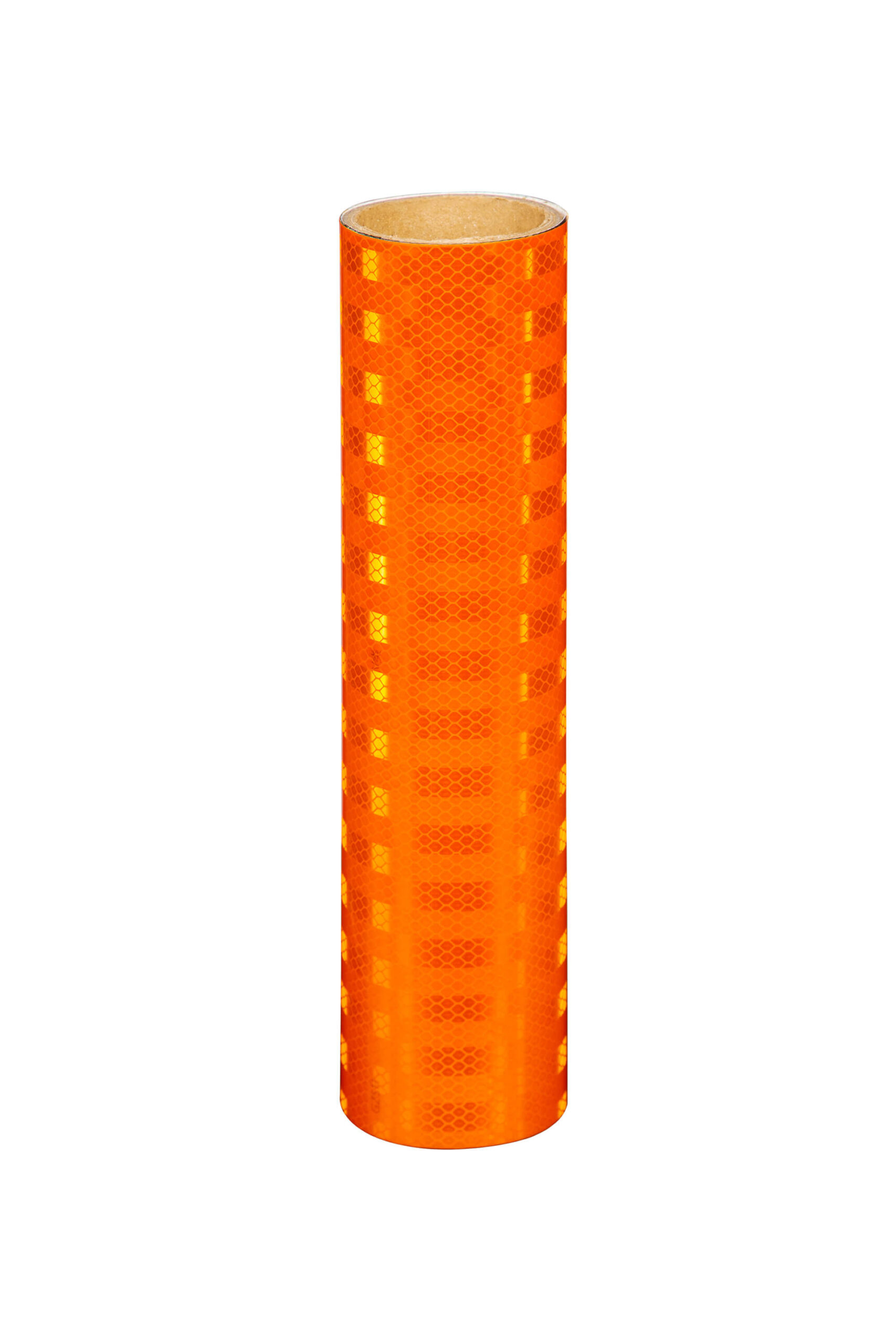

SH-1026 Orange

SH-1027 Brown

SH-1029 Fluorescent Yellow and Green

SH-10210 Fluorescent Orange

SH-10211 Black and Yellow

Typical Retroreflection

Typical Coefficient of Retroreflection when Measured per ASTM E-810. Average of 0° and 90° Rotations. (cd/lx/m2)

Color Observation Angle Entrance Angle -4° 30°

White 0.2° 160 80

0.5° 80 40

Yellow 0.2° 110 55

0.5° 55 26

Orange 0.2° 65 30

0.5° 30 15

Application Guidelines

The following is a short overview of application guidelines. Please refer to the various Technical Data Bulletins supplied by Guangzhou Shenghui Optical Technology for a complete set of procedures. SH102 should be conditioned above 18°C(65°F) for at least 24-hours prior to application.

Application should occur using a squeeze roll applicator with a firm rubber roller. Hand application in not recommended. SH102 is designed primarily for application to flat surfaces. Sign substrates should be cleaned prior to application. Wipe surfaces with rubbing alcohol (or similar solvent cleaner) and allow the surface to completely dry prior to application. Wet application method is NOT recommended. After lamination, finished signs should be stored indoors at ambient temperatures for at least 24 hours prior to installation or exposure to outdoor environments. Store finished signs on edge in an upright position. Do not stack in outdoor environments or allow sign packages to become saturated with water. Store sign packages indoors in an upright position.

Storage

Store in a cool, dry area. Use within 1-year of receipt of the product.